The helical coil steam generator is a specific type of Tube and Shell Heat Exchanger known for having a higher heat transfer coefficient than many other designs.

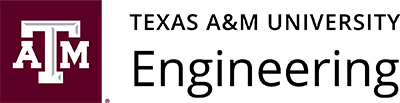

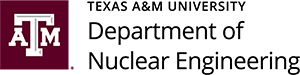

We have designed, constructed, and operated three test facilities with main focus on the shell side flow for a specific design of the helical coil steam generator. The three facilities include:

- one-to-one curved single interface between bundles,

- one-to-one curved five bundle test section and

- one-to-one straight five bundle test section.

Studies focus on the effect the complex geometry plays on flow properties. The state of the art facilities use refractive index matching Particle Image Velocimetry (PIV), Laser Doppler Anenometry (LDA), and Hot Film Anenometry, to study the cross-flow behavior of the fluid between bundles.

Pressure measurements across the bundles are also conducted to compare the effect that the different geometry has on current tube and shell pressure drop correlations. Dynamic Pressure Transducers and Pressure Sensitive Paint (PSP) are also used to study the change in pressure around the surface of the individual rods within a bundle.

Experimental Studies

Flow Visualization Studies

Flow Induced Vibration Studies

Computational Fluid Dynamics (CFD) Simulations

The laboratory has conducted simulations of helical coil steam generator (HCSG) to further investigate the flow in these components using with large eddy simulation (LES) methods. Open-source, high-order spectral element CFD code Nek5000 is largely utilized in the laboratory. Special analysis techniques (Spectral analysis and wavelet analysis) are conducted to extract important information of the flow behavior. Validation of Nek5000 model was performed using the experimental results obtained from the test sections operated in the laboratory.

References

1) Mustafa Alper Yildiz, Haomin Yuan, et al. (2020). “Numerical Simulation of Isothermal Flow Across Slant Five-Tube Bundle with Spectral Element Method Code Nek5000”. Nuclear Technology 206 ,pp. 296–306.

2) Mustafa Alper Yildiz, Elia Merzari, and Yassin Hassan (2019). “Spectral and Modal Analysis of the Flow in a Helical Coil Steam Generator Experiment with Large Eddy Simulation”. International Journal of Heat and Fluid Flow, 2019, 80.108486,pp. 1–16.