The Critical Heat Flux / Departure from Nucleate Boiling test loop provides a means of evaluating the DNB performance of test geometries representative of commercial pressurized water reactor (PWR) nuclear fuel. The test facility has operated at the Product Engineering Development Laboratory, which is part of the Westinghouse Columbia Fuel Fabrication Facility (Columbia, SC). The facility has been moved to our laboratory.

The Critical Heat Flux / Departure from Nucleate Boiling test loop provides a means of evaluating the DNB performance of test geometries representative of commercial pressurized water reactor (PWR) nuclear fuel. The test facility has operated at the Product Engineering Development Laboratory, which is part of the Westinghouse Columbia Fuel Fabrication Facility (Columbia, SC). The facility has been moved to our laboratory.

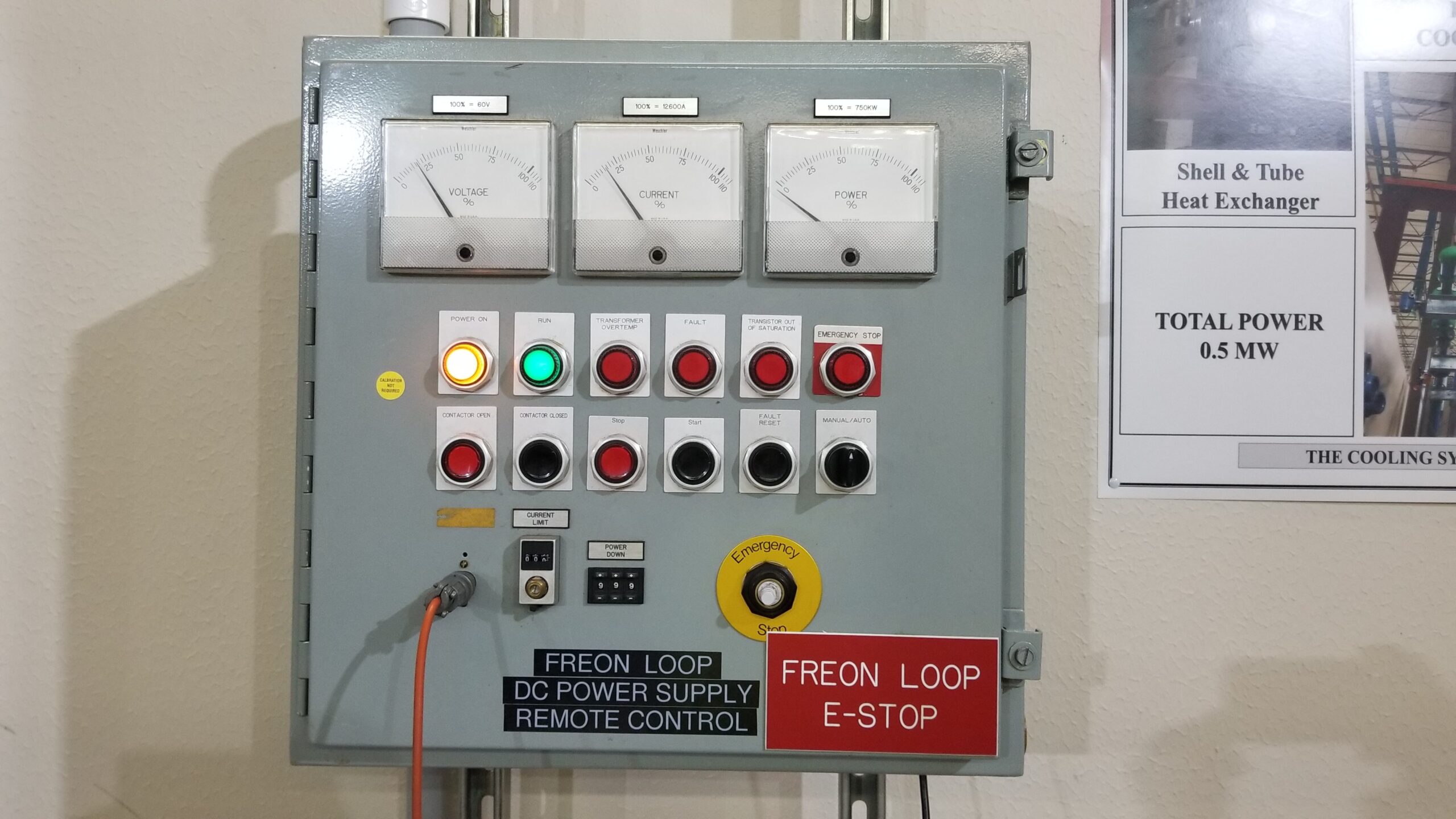

With a total power installed of 0.5 MW, 500 psia (3.5 MPa), independent cooling loop, dedicated cooling tower, the facility is able to host different fuel designs to generate new experimental data for current and advanced fuel designs. The use of Freon (R-11) and coolant, allows for achieving water-equivalent prototypical PWR conditions.

Upgrades with state-of-the-art instrumentation for temperature and void fraction measurements, in conjunction with existing instrumentation installed is the key to success for this facility.

Current test bundle features twenty-five electrically heated/instrumented rods, and organized within the 5×5 array to simulate a specific radial power shape.

The experimental facility is now in operation. Shakedown tests have been performed under different flow rates and power. Instrumentation has been upgraded with new accurate devices, and calibrated.

See time laps of the facility construction below.