The Very High Temperature Gas-Cooled Reactor (VHTR) is one of the six Gen IV reactor designs, which will generate electricity and high temperature heat for industrial applications.

The design of the VHTR includes a new passive safety system that is designed to remove heat and maintain temperatures of steel and concrete structures within safety limits, during normal operations and accident scenarios. The Reactor Cavity Cooling System (RCCS) provides an entirely ex-vessel means to reject decay heat to the environment without the need for pumps, diesel generator, or human intervention.

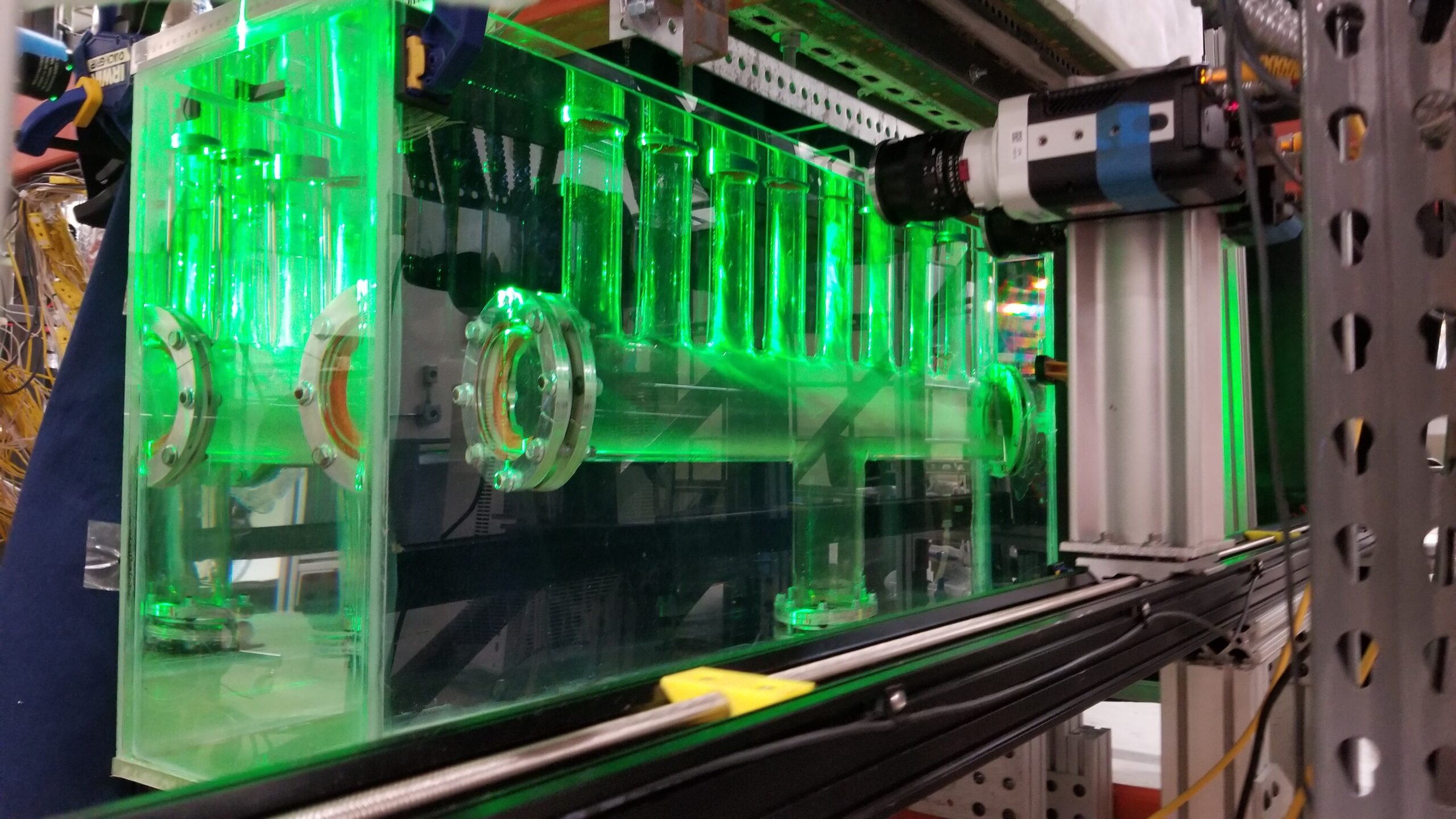

We are actively contributing to the design and optimization of this new safety system, by conducting extensive experimental and computational research aimed to gain understanding of the physical phenomena involved, and verifying the correct functionality of the system. We have designed, constructed, and operated a 1/23-scale water-cooled RCCS facility to investigate the flow behavior of the water, to study the complex heat transfer mechanisms in the reactor cavity, contributing to the overall design validation and optimization of this device. Experimental data produced are compared with simulation results, contributing to the validation of system level computer codes, and Computational Fluid Dynamics (CFD) codes.

The facility features a nine-riser panel, electric heaters, and transparent sections (manifolds, risers’ inlet/outlets, water tank) to perform flow visualization and measurements, and a large number of thermocouples to measure the temperature of coolant and cavity walls.

Particle-Image Velocimetry (PIV), Laser-Doppler Velocimetry (LDV), and Distributed Temperature Sensor (DTS) measurement techniques are being applied.

The facility was design, constructed, and operated thanks to the support of the Nuclear Energy University Program (NEUP) – DE-NE0008552, in collaboration with University of Wisconsin – Madison, and Argonne National Laboratory.

Benchmark Exercise

Experimental data sets are available for validation of system-level and computational fluid dynamics tools.

For more information please contact Rodolfo Vaghetto (r.vaghetto@tamu.edu)

List of Relevant Publications

D.Holler, R. Vaghetto, Y. Hassan, “Water temperature measurements with a Rayleigh backscatter distributed sensor”. Optical Fiber Technology, Volume 55, 102160, 2020,

D.Holler, R. Vaghetto, Y. Hassan, “High-resolution wall temperature measurements with distributed fiber optic Sensors”. International Journal of Thermal Sciences 145, 106042, 2019

NR Quintanar, T Nguyen, R Vaghetto, YA Hassan, “Natural circulation flow distribution within a multi-branch manifold.” International Journal of Heat and Mass Transfer 135, 1-15, 2019

R. Vaghetto, Y.A. Hassan, Experimental Study of a Scaled Water-Cooled Reactor Cavity Cooling System, Nuclear Technology, Volume 187, Issue 3, 2014

R. Vaghetto, Y.A. Hassan, Modelling the Thermal-Hydraulic Behavior of the Reactor Cavity Cooling System using RELAP5-3D, Annals of Nuclear Energy, Volume 73, Pages 75-83, 2014

R. Vaghetto, L. Capone, Y. A. Hassan, Experimental Study of the Effect of Graphite Dispersion on the Heat Transfer Phenomena in a Reactor Cavity Cooling System (RCCS), Nuclear Technology, volume 177, number 2, 2012

L.Capone, Y.A. Hassan, R. Vaghetto, “Reactor cavity cooling system (RCCS) experimental characterization.” Nuclear Engineering and Design, Vol. 241, Issue 12, Pages 4775-4782, 2011