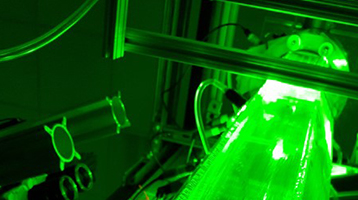

Advanced reactor technologies have generated interest for their potential to reduce fossil fuel emissions, improve energy efficiency and cut down on nuclear waste. We have designed, constructed , and operated a specialized test facility to measure hydraulic parameters and validate computational tools used in reactor design and testing. The fast reactor assembly design used is significant, not only because of the complex inner knowledge it can provide about advanced reactors, but also because the Texas A&M experiment is using the largest transparent test fuel assembly of its kind to date.

Advanced reactor technologies have generated interest for their potential to reduce fossil fuel emissions, improve energy efficiency and cut down on nuclear waste. We have designed, constructed , and operated a specialized test facility to measure hydraulic parameters and validate computational tools used in reactor design and testing. The fast reactor assembly design used is significant, not only because of the complex inner knowledge it can provide about advanced reactors, but also because the Texas A&M experiment is using the largest transparent test fuel assembly of its kind to date.

Measurements of axial and azimuthal pressure drops, and velocity fields are collected and analyzed used the state-of-the-art instrumentation and advanced techniques.

Read the full article on nuclearstreet.com

New experiments are being conducted to investigate the flow behavior with and without blockages at different locations in the bundle. New advance techniques of flow visualization are being explored. The new activity is sponsored by the Nuclear Energy University Program (NEUP), under the project DE-NE0008652

Journal Publications

1.Nguyen et al. (2017), “PIV Measurements of turbulent flows in a 61-pin Wire-Wrapped Hexagonal Fuel Bundle”, International Journal of Heat and Fluid Flow 65, 2017, pp 47-59.

2.Vaghetto et al. (2017), “Pressure Measurements in a Wire-Wrapped 61-Pin Hexagonal Fuel Bundle”, J. Fluids Eng 140 (3).

3.Brockmeyer et al. (2017), “Numerical simulations for determination of minimum representative bundle size in wire wrapped tube bundles”, Nuclear Engineering and Design 322, 577-590

4.Nguyen et al. (2017), “Stereoscopic PIV measurements of near-wall flow in a tightly packed rod bundle with wire spacers”, Experimental Thermal and Fluid Science, 92, 2018.

5.Goth et al (2018), “PTV/PIV measurements of turbulent flows in interior subchannels of a 61-pin wire-wrapped hexagonal fuel bundle”, International Journal of Heat and Fluid Flow 71, 295-304.

6.Goth et al. (2018), “Comparison of experimental and simulation results on interior subchannels of a 61-pin wire-wrapped hexagonal fuel bundle”, Nuclear Engineering and Design 338, 130-136.

7. Nguyen et al. (2019), “Turbulent flow and vortex characteristics in a blocked subchannel of a helically wrapped rod bundle”, Experiments in Fluids, 60, 1-28.

8. Nguyen et al. (2019), “High-fidelity velocity measurements in a totally blocked interior subchannel of a wire-wrapped 61-pin hexagonal fuel bundle”, Nuclear Engineering and Design, 353, 110234.

9. Nguyen et al. (2020), “Experimental investigation of turbulent wake flows in a helically wrapped rod bundle in presence of localized blockages”, Physics of Fluids, 32, 7.

10. Childs et al. (2020), “Experimental study on the effect of localized blockages on the friction factor of a 61-pin wire-wrapped bundle”, Journal of Fluids Engineering, 142, 11, 111211.

11. Childs et al. (2021), “Experimental determination and analysis of the transverse pressure difference in a wire-wrapped rod bundle”, International Journal of Heat and Mass Transfer, 170, 120958.

12. Bovati et al. (2021), “RANS simulations for transition and turbulent flow regimes in wire-wrapped rod bundles”, International Journal of Heat and Fluid Flow, 90, 108838.

13. Kim et al. (2021), “Prediction of pressure drop in hexagonal wire-wrapped rod bundles using artificial neural network”, Nuclear Engineering and Design, 381, 111365.

14. Bovati et al. (2022), “Pressure drop and flow characteristics in partially blocked wire wrapped rod bundles”, Annals of Nuclear Energy, 165, 108671.

15. Chen et al. (2022), “The blockage model of Upgraded Cheng and Todreas correlation for pressure drop in hexagonal wire-wrapped rod bundles”, Nuclear Engineering and Design, 395, 111874.

16. Bovati et al. (2022), “Analysis of the turbulent flow in a partially blocked wire-wrapped rod bundle using LES with wall functions”, International Journal of Heat and Fluid Flow, 97, 109041.

17. Kim et al. (2022), “Prediction of flow regime boundary and pressure drop for hexagonal wire-wrapped rod bundles using artificial neural networks”, Physics of Fluids, 34, 10.

18. Bovati et al. (2022), “Implementation of a CFD methodology for computing subchannel friction factors and split parameters in wire-wrapped rod bundles”, Nuclear Engineering and Design, 397, 111952.

19. Menezes et al. (2023), “Flow characteristics within an interior subchannel of a 61-pin wire-wrapped hexagonal rod bundle with a porous blockage”, Physics of Fluids, 35, 2.

20. Bovati et al. (2023), “Validation of RANS simulations on a 61-pin wire-wrapped fast-reactor fuel assembly under the presence of localized blockages”, Nuclear Engineering and Design, 413, 112512.

21. Menezes et al. (2023), “Experimental characterization of pressure and friction factor in an interior subchannel of a 61-pin wire-wrapped rod bundle with a porous blockage”, Physics of Fluids, 35, 11.

22. Bovati et al. (2023), “Assessment of RANS and LES in predicting the flow in a 61-pin wire-wrapped bundle with a porous blockage”, Nuclear Engineering and Design, 414, 112587.

23. Bovati et al. (2023), “Numerical study of the impact of blockages on the Thermal-Hydraulic performance of 19 and 61-pin Wire-Wrapped bundles with conjugate heat transfer using RANS”, Annals of Nuclear Energy, 194, 110122.

24. Melsheimer et al. (2024), “Particle image velocimetry measurements for transition flow regime through a porous blocked subchannel in a 61-pin wire-wrapped bundle”, Nuclear Engineering and Design, 424, 113314.

25. Kim et al. (2025), “Flow Regime Classification in Hexagonal Wire-Wrapped Fuel Assembly Using Advanced Machine Learning Models”, Nuclear Technology, 211, 3, 452-475.

26. Melsheimer et al. (2025), “Fluid Dynamics Effects of a Porous Blockage on Laminar Flow in the Interior Subchannels of a 61-Pin Wire-Wrapped Rod Bundle”, Nuclear Technology, 211, 4, 725-741.